By Sui Tan, Metropolitan Transportation Commission (MTC)

In my previous blog, I talked about why IRI contributes little to reduction of deferred maintenance from the asset management perspective. I will now continue to discuss if IRI will be a better performance indicator in pavement preservation, since pavement preservation is one of the national goals in the Moving Ahead for Progress in the 21st Century (MAP-21) act.

Pavement Preservation

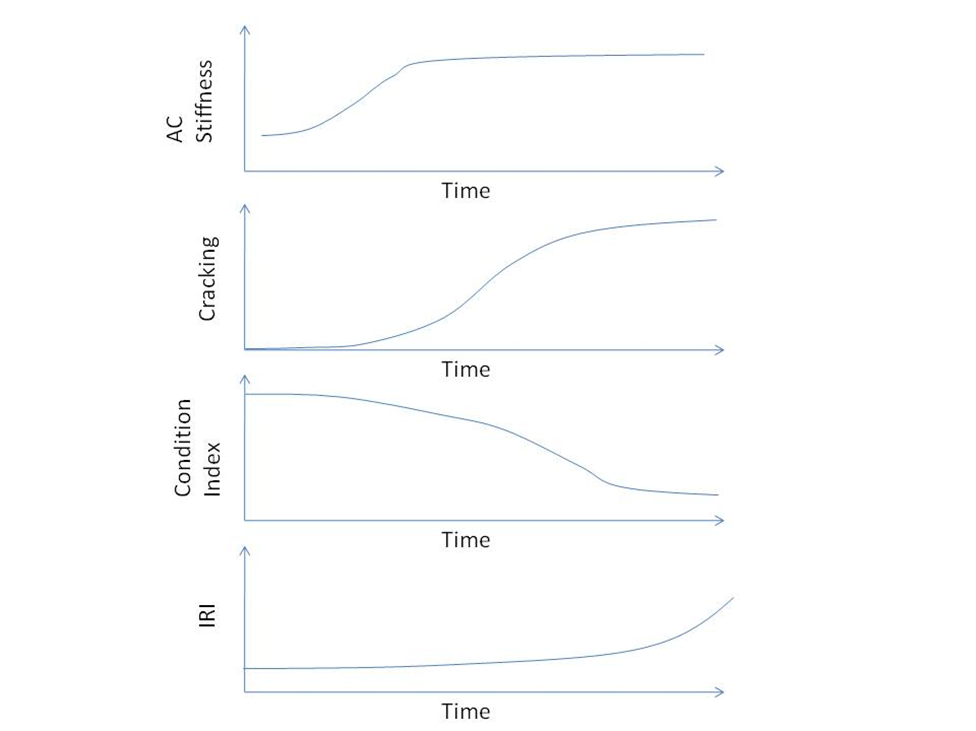

From the engineering perspective, at the time of construction, the asphalt cement starts to age-harden. As it hardens, the asphalt cement and asphalt concrete loses its ability to expand or stretch without cracking. So after some time cracks start developing, which leads to further cracking and decrease in condition index, as shown in the graphs below. IRI stays relevantly constant through much of this, but as the cracking increases and the condition index deteriorates, the IRI starts to increase. However, by the time the IRI has increased significantly, the cracking may have caused significant structural deterioration in the pavement – well beyond what preventive maintenance treatments included in a pavement preservation program can address. So while IRI can be used to identify pavements that are beyond the point where most preservation treatments can be applied, it does little to identify when to apply preservation treatments.

Performance Management Indicator

In performance management, there are “leading” and “lagging” indicators. A lagging indicator is usually easy to measure but hard to influence. An example is using weight loss as a goal. You step on a scale and you know your weight. However, the weight is a lagging indicator. It is too late when the scale says you are 10 pounds overweight. So how do you reach your goal? Leading indicators like the amount of calories intake and burned will be good ones to start with.

In pavement management, IRI measures ride quality or smoothness of pavement. It is easy to measure and is used by all state highway agencies for the Highway Performance Monitoring System (HPMS) reporting. However, the IRI increase is only noticeable when certain amounts of distresses have appeared, and is less sensitive to cracking distresses. Hence, when it comes to pavement preservation, IRI is a lagging indicator for preventive maintenance. On the other hand, for example, PCI based on ASTM D6433 standard, is an excellent leading indicator, enabling an agency to apply preventive maintenance when the first sign of distress appears. This is because pavement rating for PCI is based on low, medium, and high severity of various distresses and their quantity.

For more information, contact Sui Tan at: stan@mtc.ca.gov